Harris Compressed Air Audits

Compressed air audits can identify opportunities for cost savings and contribute to a more efficient and streamlined operation. Compressed air is known as a significant energy consumer in your plant— if not the largest. Despite its widespread usage in diverse manufacturing applications, it remains the most misunderstood utility and represents a key area for major cost reduction.

Reduce Compressed Air Costs by 25-50% With an Air Audit

When trying to reduce operating expenses related to compressed air, companies often overlook the potential savings that effective management of their compressed air systems can bring. Experts estimate that a majority of users could achieve cost reductions ranging from 25-50%.

Harris specializes in professional compressed air audits designed to unveil substantial cost-saving opportunities by assessing current flow rates, energy consumption, and operating pressure. These audits provide crucial data for identifying areas of improvement within your air system. Many plants currently operate with 50% more compressed air horsepower than necessary for their operations. Undergoing an air audit not only leads to gradual operating cost reductions but also brings about positive environmental benefits.

Did You Know...

Utility companies often offer rebates covering up to 100% of energy study costs. Some also provide funding for energy-saving projects, contributing 50% of the project cost or 12 cents for every kilowatt saved for a year.

Get a Professional Air Audit From Harris

Almost all manufacturing facilities tend to expend more funds on operating and maintaining their compressed air system than required. Additionally, a significant portion of these companies deal with low quality compressed air, stemming from various poor practices—both historical and current. These include inefficient equipment choices, poor system design and layout, insufficient maintenance practices, inefficient compressor controls, a shortage of useful storage, and more.

Our seasoned technicians possess the expertise to perform a comprehensive compressed air audit and suggest cost-saving options based on the gathered data. Contact us today to request an air audit and start saving money.

Benefits of a Compressed Air Audit

- 25-50% Cost Savings

- Reduce the risk of equipment failure

- Reduce energy and repair costs

- Reduce energy consumption

- Increase productivity

- Increase reliability

- Reduce unplanned downtime

- Improve the quality of compressed air

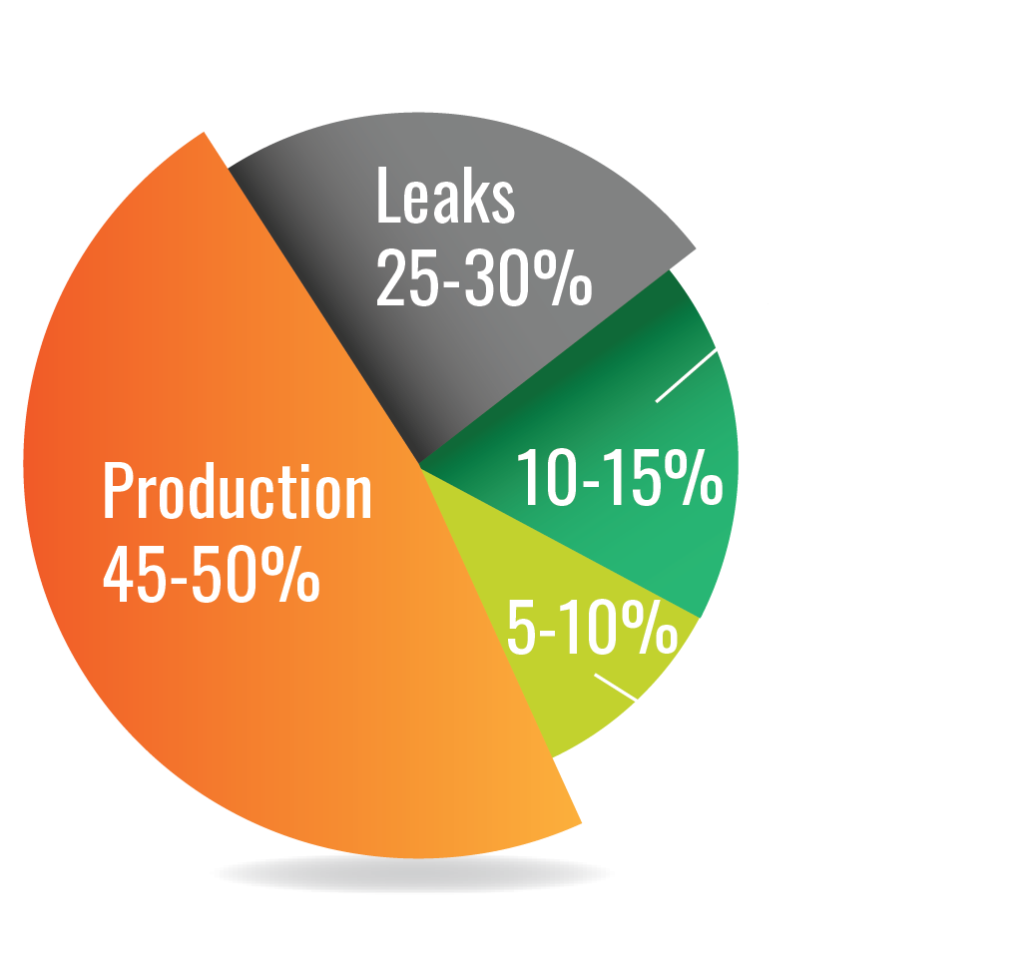

Where is Most Compressed Air Wasted?